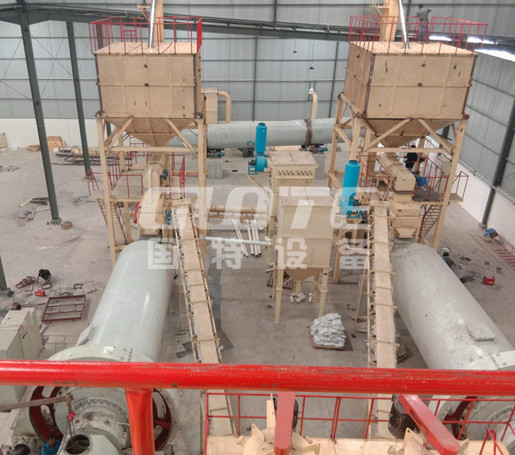

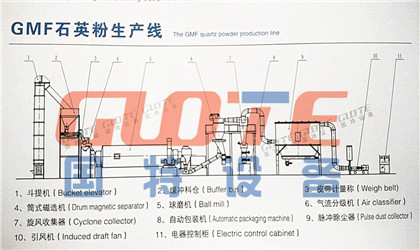

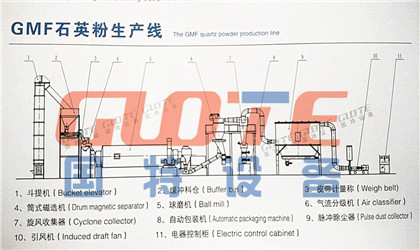

GMF Ball Mill and Vertical Classifier Production Line

GMF Ball Mill and Vertical Classifier Production Line。Suitable for microsilica, heavy calcium, aluminum, graphite powder and superfine powder processing. With a yield of material pollution, product quality and stability, controllable particle size distribution characteristics

【Material size】: 5mm

【Production capacity】: 1-10ton/hour

【Model】: GMF

【Applications】: Mineral processing, chemical industry, medicine, building materials, etc

【Applicable materials】: Soft material: calcite, marble, limestone, barite, gypsum, slag etc.

Hard material: quartz, felspa, carborundum, corundum, fine cement etc.

GMF Ball Mill and Vertical Classifier Production Line

GMF Ball Mill and Vertical Classifier Production Line。Suitable for microsilica, heavy calcium, aluminum, graphite powder and superfine powder processing. With a yield of material pollution, product quality and stability, controllable particle size distribution characteristics

【Material size】: 5mm

【Production capacity】: 1-10ton/hour

【Model】: GMF

【Applications】: Mineral processing, chemical industry, medicine, building materials, etc

【Applicable materials】: Soft material: calcite, marble, limestone, barite, gypsum, slag etc.

Hard material: quartz, felspa, carborundum, corundum, fine cement etc.

Product advantages

1.Scope of applicationSoft material: calcite, marble, limestone, barite, gypsum, slag etc.

Hard material: quartz, felspa, carborundum, corundum, fine cement etc.

2.Technical maturity , Saving energy and Protecting environmentThe whole production process was going on with advanced wear resistant defending. The inner layer of ball mill can be made

of ceramic or quartz. And choose ceramic ball or quartz ball as grind medium. The whole classify system takes potsherd defending

so that the whole production don’t touch metal to guarantee the product’s purity and prolong the equipments’service time

3.Operation Simplification , High automation equipmentIts system and configure are optimized by theory and practice to decrease power consumption furthest. The dust collector in the

production line are designed superiorly which can avoid dust leak and accord with government’s policy.

Working principle

Less than -10 purpose materials from the feed device evenly into the mill warehouse into the compound by the air shaft spiral, warehouse equipped with ceramic liner, built with different specifications steel jade ball, rotating cylinder produces centrifugal force to the ball a certain height media After the fall, have an impact on the material and abrasive. Meet the requirements of the powder is discharged through the discharge grate plate to complete the grinding operation. After grinding material from the inlet port into the grading machine, by adjusting the classifier wheel (frequency control, stepless) speed, and with a reasonable secondary air, in grading the area to form a reasonable and stable gas-solid two phase flow, the use of the classifier wheel rotation centrifugal force, and the suction fan negative pressure generating attractive interaction, to achieve effective grade material. Coarse particles from coarse material return means return ball milling was continued and finished by the automatic packaging machine to complete packaging jobs. The whole system is equipped with ESP, the use of more advanced electromagnetic pulse automatic cleaning, dust after carrying gas into the dust collector, bag filter dust is attached at the outer surface of the dust bag in the role of pulse cleaning gas scattered bottom is collected, filtered through a clean gas into the atmosphere by the fan.

Copyright © 2005-2006 State Special Mining Equipment Co., Ltd. Weifang Allrights ReservedBusiness Phone: 086-0536-3685656 Sale Telephone: 0536-3163838 Fax: 0536-3162298