GF Air Classifier

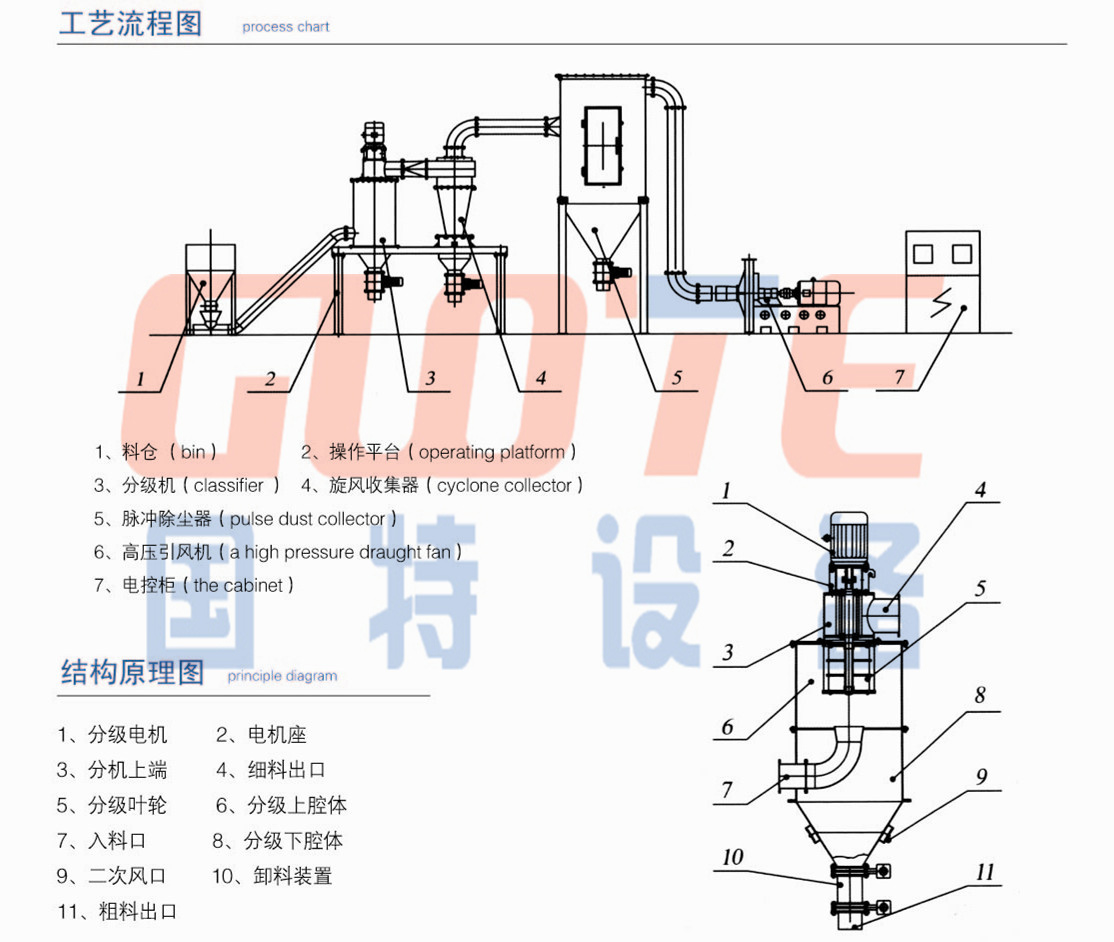

The classifying device is composed of pneumatic classifier, cycione collector induced draft fan, control cabinet and so on .

【Material size】: 0-1mm

【Production capacity】: 0-50 tone/hour

【Model】: Series GF

【Applications】: ultrafine powder classifying

【Applicable materials】: Silicon powder, calcium carbonate, feldspar powder, alumina, bauxite, kaolin, talc, graphite, etc

GF Air Classifier

The classifying device is composed of pneumatic classifier, cycione collector induced draft fan, control cabinet and so on .

【Material size】: 0-1mm

【Production capacity】: 0-50 tone/hour

【Model】: Series GF

【Applications】: ultrafine powder classifying

【Applicable materials】: Silicon powder, calcium carbonate, feldspar powder, alumina, bauxite, kaolin, talc, graphite, etc

Product advantages

1High grading precision to strictly control the size of particle with the special design.

2The grading point can be freely adjusted by the grading rotor and the air-processing capacity to get the wanted product in large scope.

3The vertical single impeller makes the flow field stable with high processing capacity and high grading efficiency.

4Multi-pole concatenated structure can separate the particles in different sizes simultaneous.

Copyright © 2005-2006 State Special Mining Equipment Co., Ltd. Weifang Allrights ReservedBusiness Phone: 086-0536-3685656 Sale Telephone: 0536-3163838 Fax: 0536-3162298